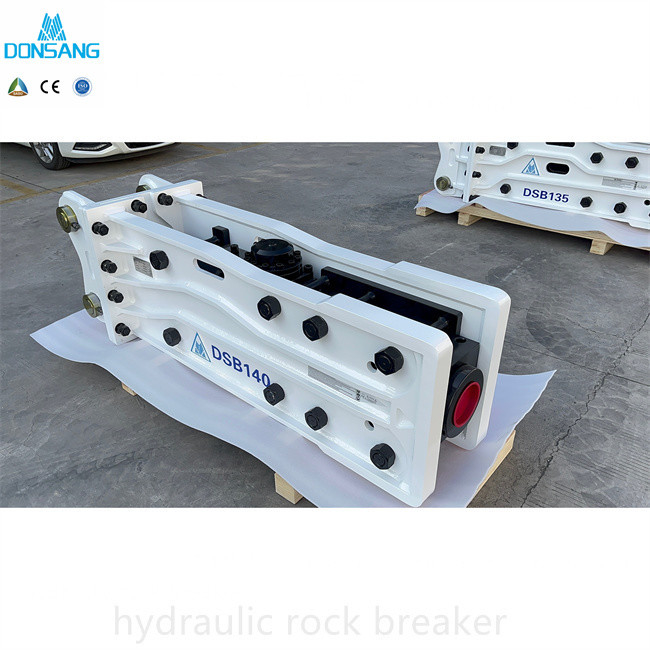

Donsang Excavator Attachment Hydraulic Hammer Breaker HB20G HB30G for 20 - 30 Tons Excavator

About Us:

Donsang Machinery Co.,Ltd was found in 2012, located in Suzhou, a beautiful garden city which is nearby the several sea port like Shanghai ,Ningbo, Taicang. Over the decades of effort by the group, the branch offices was established now in UAE and North America.

The company its serviced the hydraulic breaker as the start and now covered all kinds of excavator attachments for the mining ,construction, recycling, tunnel , underwater , farming, army work etc., industries. From the small carrier like BOBCAT to the giant machine like the mining excavators of different brads.

6S management of the factory, fully certificated of the products, with those high standard quality product ,the efficient team work and reasonable price terms that there are more than 43 countries valued clients are having the long-term relationship.

Donsang Machinery Co.,Ltd wish to provide more valuable concept and actions to our partners so that your every words or questions are important for us.

Product Description:

Hydraulic Breaker Hammer is a powerful and efficient tool for breaking and demolishing concrete, asphalt, rocks, and other materials. It is designed with a robust and reliable construction that offers a high impact force of 5250 J and oil flow of 170 - 240L/min. The total length (with mount cap & tool) is 2904mm, and the chisel diameter and length are 150mm and 1300mm, respectively. Our Hydraulic Breaker Hammer is suitable for a wide range of applications, including excavations, demolition, quarrying, dredging, and tunneling. It features a low noise level, easy maintenance, and a long service life. Our Hydraulic Breaker Hammer is the perfect choice for any contractor looking for a reliable and powerful tool to get the job done.

Our All Models Data

| Item |

Unit |

DSB53 |

DSB68 |

DSB75 |

DSB85 |

DSB100 |

DSB135 |

DSB140 |

DSB150 |

DSB155 |

DSB165 |

DSB175 |

DSB180 |

Total Length

(WITH MOUNT CAP& TOOL) |

SIDE TYPE |

mm |

1,140 |

1,330 |

1,699 |

1,767 |

1,939 |

2,289 |

2,414 |

2,603 |

2,776 |

2,919 |

3,189 |

3,253 |

| OPEN TYPE |

mm |

1,372 |

1,641 |

1,719 |

2,160 |

2,339 |

2,719 |

3,030 |

2,904 |

3,119 |

3,359 |

3,617 |

3,753 |

| BOX TYPE |

mm |

1,400 |

1,658 |

1,741 |

2,200 |

2,400 |

2,766 |

3,075 |

3,075 |

3,250 |

3,450 |

3,711 |

3,760 |

Operation Weight

(WITH TOOL) |

SIDE TYPE |

kg |

137 |

281 |

398 |

618 |

845 |

1,605 |

1,812 |

2,530 |

2,752 |

3,189 |

4,055 |

4,586 |

| OPEN TYPE |

kg |

132 |

275 |

390 |

604 |

920 |

1,784 |

1,975 |

2,750 |

2,818 |

3,514 |

4,370 |

4,600 |

| BOX TYPE |

kg |

161 |

348 |

456 |

675 |

978 |

1,942 |

2,174 |

2,895 |

2,906 |

3,586 |

4,480 |

4,658 |

| Operation Pressure |

kgf/cm2 |

90~120 |

110~140 |

120~150 |

130~160 |

140~170 |

160~180 |

160~180 |

160~180 |

160~180 |

160~180 |

160~200 |

180~220 |

| psi |

1,280~1,706 |

1,564~1,990 |

1,706~2,133 |

1,706~2,133 |

1,990~2,417 |

2,275~2,559 |

2,275~2,559 |

2,275~2,559 |

2,275~2,559 |

2,275~2,559 |

2,275~2,559 |

2,559~3,128 |

| Oil Flow |

l/min |

25~45 |

40~70 |

50~90 |

60~100 |

80~120 |

120~150 |

120~150 |

170~240 |

170~240 |

190~250 |

220~260 |

220~260 |

| gpm |

6.6~11.9 |

7.9~13.2 |

13.2~23.8 |

15.8~26.4 |

21.1~31.7 |

31.7~39.6 |

31.7~39.6 |

44.9~63.4 |

44.9~63.4 |

50.1~66.0 |

58.1~76.5 |

58.1~76.5 |

| Impact Rate |

bpm |

550~1000 |

450~950 |

400~900 |

400~800 |

450~630 |

350~500 |

250~400 |

380~480 |

320~450 |

280~370 |

240~320 |

210~300 |

| Nitrogen |

bar |

14-17 |

14-17 |

14-17 |

14-17 |

14-17 |

14-17 |

14-17 |

18-22 |

17-20 |

17-20 |

22-25 |

22-25 |

| Chisel Diameter |

mm |

53 |

68 |

75 |

85 |

100 |

135 |

140 |

150 |

155 |

165 |

175 |

185 |

| inch |

2.08 |

2.67 |

2.95 |

3.34 |

3.93 |

5.31 |

5.51 |

5.9 |

6.11 |

6.48 |

6.88 |

7.27 |

| Chisel Length |

mm |

550 |

700 |

750 |

850 |

1,000 |

1,200 |

1,200 |

1,300 |

1,400 |

1,400 |

1,500 |

1,600 |

| Chisel Weight |

kg |

9 |

18 |

29 |

32 |

57 |

121 |

137 |

170 |

193 |

227 |

272 |

320 |

| Hose Size |

mm |

13 |

13 |

13 |

19 |

19 |

25 |

25 |

25 |

32 |

32 |

32 |

32 |

| inch |

PF1/2'' |

PF1/2'' |

PF1/2'' |

PF3/4'' |

PF3/4'' |

PF1'' |

PF1'' |

PF1'' |

PF1-1/4'' |

PF1-1/4'' |

PF1-1/4'' |

PF1-1/4'' |

| Noise Level |

m |

4/8 |

5/10 |

6/12 |

6/12 |

7/14 |

16-22 |

16-22 |

26-35 |

26-35 |

35-40 |

38-45 |

42-48 |

| Suitable Exca |

ton |

2.1~4.0 |

4.8~8.0 |

6.0~9.0 |

8.0~12.5 |

12~15 |

20~26 |

22~27 |

25-32 |

26~35 |

30~42 |

35~45 |

45~50 |

| Impact Force |

j |

355 |

560 |

790 |

1320 |

1980 |

3450 |

3720 |

5250 |

5750 |

7040 |

14800 |

17550 |

Features:

- Product Name: Hydraulic Hammer Breaker

- Warranty: 1 Year

- Impact Force: 5250 J

- Total Length (With Mount Cap & Tool): 2904 Mm

- Suitable Excavator: 25 -32 Ton

- Operation Pressure: 160 -180 Kgf/m2

- Features: Excavator Rock Hammer, Hydraulic Breaker Factory, Breaking Rock Hammer

Technical Parameters:

| Technical Parameter |

Value |

| Impact Force |

5250 J |

| Chisel Weight |

170 Kg |

| Hose Size |

25 Mm |

| Nitrogen |

18 - 22 Bar |

| Total Length (With Mount Cap & Tool) |

2904 Mm |

| Product Name |

Hydraulic Hammer Breaker |

| Suitable Excavator |

25 - 32 Ton |

| Chisel Length |

1300 Mm |

| Operation Pressure |

160 - 180 Kgf/m2 |

| Chisel Diameter |

150 Mm |

Applications:

The DONSANG DSB150 Hydraulic Hammer Breaker is a heavy duty excavator rock hammer ideal for breaking large rocks. It is designed for use with excavators in quarry and mining operations, as well as for demolition and construction activities. It has a total length of 2904 mm, with a mount cap and tool. It is powered by an oil flow of 170 - 240 L/Min, and has an impact rate of 380 - 480 Bpm. The operation weight of the hammer is 2750 mm.

The heavy duty breaker hammer is manufactured by DONSANG, a trusted hydraulic breaker factory. It is suitable for applications such as breaking hard rock, road pavement, and concrete slabs. It is able to provide powerful force for breaking larger rocks, and can be used for breaking stones and boulders in mining and construction sites. It is also able to work in low-noise environment, making it suitable for use in residential areas.

The DONSANG DSB150 Hydraulic Hammer Breaker is a reliable, durable, and efficient excavator rock hammer ideal for breaking large rocks. It is easy to operate and maintain, and is suitable for a variety of applications. It offers superior performance and is able to handle the toughest of jobs.

Customization:

Customized Hydraulic Hammer Breaker

Brand Name: DONSANG

Model Number: DSB150

Place of Origin: CHINA

Chisel Weight: 170 Kg

Operation Pressure: 160 -180 Kgf/m2

Impact Rate: 380 -480 Bpm

Product Name: Hydraulic Hammer Breaker

Chisel Diameter: 150 Mm

We specialize in manufacturing and supplying Breaking Rock Hammer, Excavator Hydraulic Breaker, Hydraulic Breaker Chisel, Hydraulic Hammer Breaker.

Operators should pay attention to:

1. Carefully read the operation manual of the crushing hammer to prevent damage to the hammer and its carrier, and carry out effective operations.

2. After the installation of the crushing hammer pipeline, it must be thoroughly cleaned.

3. Prevent interference between the small arm of the excavator and the drill rod of the crushing hammer.

4. Keep the oil pipe joints clean at all times and prevent any debris from entering the oil pipe and crushing hammer.

5. When the crushing hammer is installed and connected to the main machine, the working pressure and flow rate of the hydraulic system of the main machine must meet the technical parameters requirements of the crushing hammer.

6. It is recommended to use anti wear hydraulic oil in general areas, and low-temperature hydraulic oil in cold areas.

7. The hydraulic oil of the crushing hammer should be replaced every 600 hours of operation, and the hydraulic oil should be kept clean at all times.

8. During operation, even if it is a short rest, keep the main engine pump in the starting state. Only when the oil temperature reaches at least 50 ℃, can the hydraulic crushing hammer and excavator work at maximum power, especially in winter when the temperature is low, and the excavator must be heated before use; At the same time, the oil temperature should not exceed 80 ℃. If the oil temperature is too high, the hydraulic system and overflow valve must be checked. Otherwise, the load of the hydraulic crushing hammer should be reduced.

9. Before operation, check whether the bolts and connectors are loose, and whether there is any leakage in the hydraulic pipeline.

10. The drill rod and guide sleeve must be lubricated with calcium based grease or composite calcium based grease, and filled once before each operation.

Support and Services:

Hydraulic Hammer Breaker Technical Support & Service

We provide technical support and service for our Hydraulic Hammer Breaker. Our team of experienced professionals will help you select the right product for your application. We also offer troubleshooting assistance, repairs and maintenance services, and replacement parts.

Our knowledgeable customer service representatives are available to answer your questions and provide assistance with installation, troubleshooting, and repairs. We are committed to providing the highest quality service and support in the industry.

Our team of experienced technicians can perform repairs and maintenance on any Hydraulic Hammer Breaker. They have the expertise and tools to diagnose and repair any issues quickly and efficiently. We also provide replacement parts and accessories to ensure your Hydraulic Hammer Breaker is operating at its best.

If you have any questions about our Hydraulic Hammer Breaker technical support and service, please feel free to contact us. We are here to help you get the most out of your product.

Packing and Shipping:

Packaging and Shipping for Hydraulic Hammer Breaker

The hydraulic hammer breaker is securely packaged in a box made of wooden to ensure that it is not damaged during transit.

FAQ:

Q: What is the brand name of the Hydraulic Hammer Breaker?

A: The brand name of the Hydraulic Hammer Breaker is DONSANG.

Q: What is the model number of the Hydraulic Hammer Breaker?

A: The model number of the Hydraulic Hammer Breaker is DSB150.

Q: Where does the Hydraulic Hammer Breaker come from?

A: The Hydraulic Hammer Breaker comes from China.

Q: What are the features of the Hydraulic Hammer Breaker?

A: The Hydraulic Hammer Breaker has features such as high power, low noise, and easy maintenance.

Q: What is the purpose of the Hydraulic Hammer Breaker?

A: The Hydraulic Hammer Breaker is mainly used for breaking rocks and pavement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!